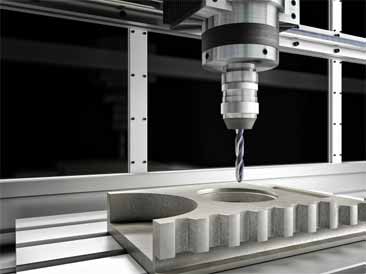

A CNC machine is a computerized machine tool that is programmed to cut complex shapes out of metal. These machines can be used for a wide range of applications in the manufacturing industry. In order to operate a CNC machine, you must first know how they work and what they are capable of. This article will teach you all about CNC machines!

How Does CNC Machine Work?

The CNC machine is controlled by a G-code programming language as it cuts through metal pieces. G-codes tell the CNC machine where to move and what actions should be taken at each point along the way. When commands are given, these will typically lead to the spindle and bit moving. This is done to prepare for cutting, which means the programming will be completed prior to starting. CNC machines use a number of different types of spindles with specific functions. The main function of the spindle is as a power source that runs between 8,000 rpm and 30,000 rpm depending on the machine.

How to operate a CNC machine?

If you’re looking for your first “CNC job” and want some tips on how to operate one, keep reading! First, a CNC machine is simply the best way to cut metal. There are many reasons for this, but here are three of the most important:

- CNC machines save businesses money in labor costs. They don’t need operators after they are programmed.

2. CNC machines allow you to cut shapes that would be impossible with conventional tools.

3. CNC machines produce parts that are of the same high quality every time.

Now, to get started with operating a CNC machine you’re going to need some basic training. The first thing you should do is enroll in an online metalworking course, or take a class from a local school or community college; this can be done in one night or weekend. After learning general metalworking, you’ll want to focus your studies and take a course in CNC machining. If you have already taken metalworking classes before, then there is nothing stopping you from starting right away!

Who Uses CNC Machines?

CNC Machines are used in industries such as aerospace, automotive, industrial products, and electronics just to name a few. They are popular due to their ability to produce complex parts from a wide range of materials.

What Are Some Of The Safety Precautions When Operating A CNC Machine?

A few things that need to be well taken care of while using a CNC Machine are having proper ventilation, securing all moving components (such as the table and head), using safety equipment such as goggles and gloves. When cutting is done, you should always turn the spindle off before removing material from the work area or unplugging its power source.

Conclusion

CNC machines are a technology that has been popular for decades in the manufacturing industry. These computer-controlled milling tools work at high speeds to cut, shape, and drill metal parts with precision accuracy. If you’ve ever wondered what they are or how they operate, we have all of the information you need right here!

We hope this article is helpful and informative as it provides an overview of what a typical machine does during the machining process. In addition, there is also an outline on getting started with operating your own CNC machine so let us know if you want any more info about these awesome devices!